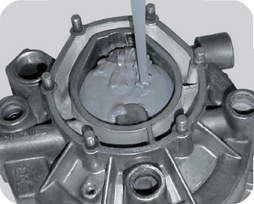

Aluminium Linning

Liquid epoxy system for industrial maintenance with similar characteristics as aluminum

Changed liquid epoxy system, containing aluminum filler resistant to high temperatures. It can be machined, sanded, driller and ground. It has characteristics similar to aluminum. It is indicated to recover aluminum cast or injected parts; molds maintenance and repair. Applicable with brush and at thickness of 1 to 2 mm