Learn how Cesar Containers ensured maximum sealing using Hard RR 500 ECO Sealant and Tacky-Tape® Tape.

Client:

Headquartered in Aparecida de Goiânia/GO and five more branches, Cesar Containers has been operating in the civil construction and logistics market for over 35 years. It offers services for the leasing and commercialization of containers and construction modules, storage of goods and transport of heavy loads.

Problem:

The company’s solutions in modular construction and containers are all over the country and serve the most diverse areas, such as events and housing, for example. For this reason, if an item presents a problem, maintenance costs would be very high, as they would need to move a team to the place where the product is just to solve a problem. This rework is synonymous with financial loss and loss of time. Precisely for this reason, the company did not want to suffer from this problem.

One of the ways to eliminate rework is to ensure the watertightness of your products. But, the task of having a 100% waterproof item is not as simple as it may seem. Since the low slope of the roof can result in faulty water flow, due to capillarity. To illustrate this phenomenon, we can think of a glass of water. If you turn it quickly, the water will cascade, but if the movement is slow and the object assumes a smaller angle, the liquid will run over the edge of the container. We can consider the same principle when thinking about the slope of a roof, the smaller the angle, the easier for water to “rise” and enter through the space between the sheets. Therefore, in cases like this, the products used in the sealing have to fulfill their function to the fullest.

For this reason, Cesar Containers needed to find solutions that would guarantee the complete sealing of its products. Contributing to a more efficient installation would be a bonus.

Solution:

Under the technical consultation of the salesperson Thamara Salgado Viana, the points where the company could have a gain in quality and productivity were mapped. The first change was the replacement of the sealant that was used on the head of the screws, which are points that require attention to avoid water infiltration and leaks. It means that, the Hard RR 500 ECO Sealant Sachet , started to be used, which has excellent resistance to weathering and aging. In addition to quality, the process would gain in efficiency, since application is quick and easy, even in hard-to-reach places.

Another change was in the material used to ensure the seal between the sides of the containers and the tiles. Before this application needed a non-drying butyl sealant, which although it met the demand, it did not add in efficiency when it came to applicability. This is because the application must be done in a continuous pass and then needs to be finished.

Having it in mind, the company started using Tacky-Tape®, a tape specially developed to seal longitudinal and transverse seams. Compared to the product used before, the application of the tape is much more practical, as it is only necessary to apply the tape and then remove the paper, which has brought productivity to the service. In terms of quality, its excellent adhesion and superior elasticity prevent the passage of water, moisture and dust.

Conclusion:

Cesar Containers was able to guarantee the complete and lasting sealing of its products. This could be proven right away in the tightness tests carried out by the company before implementing the use of the solutions suggested by Hard.

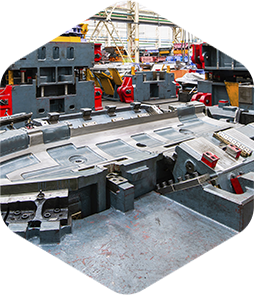

The test consisted of assembling a container and applying RR 500 ECO Sealant and Tacky-Tape®, and then filling the gutters located on the ceiling with water. After 24 hours of immersion, it was observed that there were no infiltration points or leaks. It means that the sealing was maximum and would not bring more problems that would require some maintenance.

In addition to that, the ease of application of both solutions influenced the exchange. Besides not having losses with rework, the company was able to gain more efficient processes and less time invested in sealing. Because the chosen products have an easy and quick application, as an example, see below the Sealant RR 500 ECO being applied.

Do you want to know how we can bring more quality and efficiency to your work routine? Contact us and discover our solutions.

?

*Case study carried out in October 2019.

Comentários

Ainda não há comentários. Seja o primeiro a comentar.