Did you know that the production of casting models and negatives can be up to 24 times faster? This is possible if you replace the conventional reproduction system with Resin PC 26 + Hardener G 226. This reduction in service time is very important to ensure maximum efficiency for the production process and, consequently, increase the profitability of your business.

Continue reading and learn more about this solution Hard! At first, we present the main characteristics of the products. Soon after, we explain how Resin PC 26 + Hardener G 226 can contribute to a productivity leap in the production of models and negatives for casting.

What is PC 26 Resin and G 226 Hardener?

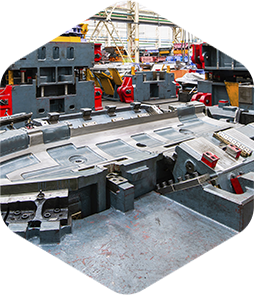

The PC 26 Resin and G 226 Hardener is a fast curing polyurethane system for part reproduction in up to one hour. In foundry, it can be used to make a negative and/or to reproduce pieces to be plated.

In addition to foundry, this solution can be used in the automotive, ceramics, footwear and plastics industries. It is indicated for several stages of the production process, such as the manufacture of models, prototypes and matrices, for example. Click here to learn more about the applications of this kit.

How can PC 26 Resin and G 226 Hardener increase productivity in the production of cast templates and negatives?

As it is a fast curing system, PC 26 Resin and G 226 Hardener allow demolding in up to one hour. While this demolding time increases to up to 24 hours when using a conventional reproduction system. But what impact does this feature have on your production line?

Most importantly, it is possible to manufacture more tools in less time. That is, if using the conventional system it takes 24 hours to produce a part, for example; when using this Hard solution, in the same period of time, it is possible to produce 24 items.

This feature can make a big difference in the delivery of an urgent service, avoid delays or simply to make the production line more efficient. In addition to that, the productivity achieved can also be reflected in financial gains. Once the faster a part is delivered, the faster the company can receive for the service provided.

More than productivity! Save and improve the end result of your tooling

In addition to productivity gains, PC 26 Resin and G 226 Hardener can guarantee higher quality casting models and negatives. That’s because these solutions perfectly reproduce the details and have an imperceptible contraction. These characteristics have a great impact on the final result of the part produced, making it possible to deliver items with an excellent level of finishing to the end customer.

It is also important to point out the savings that the mixing ratio makes possible. Since it is recommended to use 100gr of PC 26 Resin, 100gr of G 226 Hardener and 300gr of HF 32 or EF 35P filler. By doing this, it is possible to increase the volume of the mixture and, consequently, reduce its final cost.

More efficiency and quality for your production line

As we have seen in this article, making casting models and negatives up to 24 times faster is possible when using products designed for efficiency. With Hard solutions it is possible to produce tooling in up to an hour, with a very high level of detail and with greater economy.

What are you waiting for having the efficiency and quality of PC 26 Resin and G 226 Hardener in your foundry? Get in touch with one of our experts right now and take a leap in productivity with Hard solutions.

?

Comentários

Ainda não há comentários. Seja o primeiro a comentar.