Injectable Adhesive – EP 131

Injectable Epoxy-Based Structural Chemical Anchor

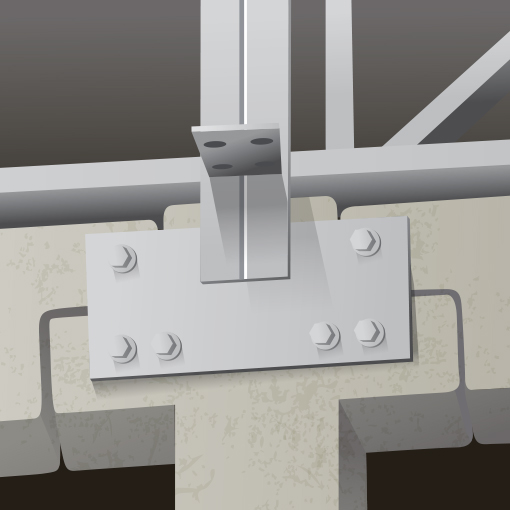

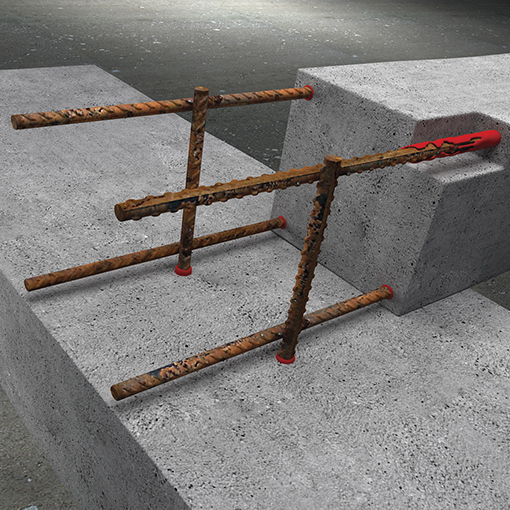

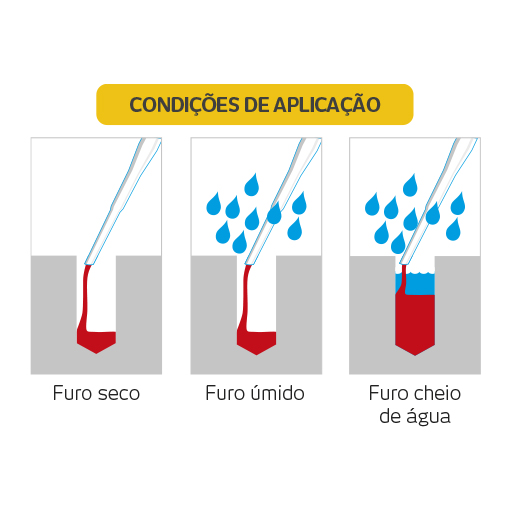

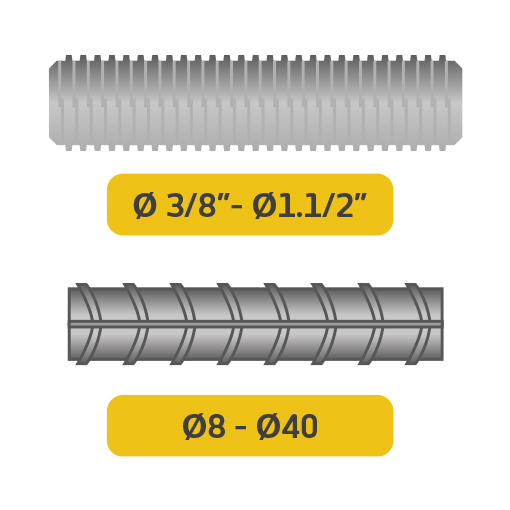

The EP 131 injectable adhesive is indicated for threaded bars and rebars anchorage in concrete. It has the strongest slow cure system in the market, ensuring high loads with high performance. It also has international certifications and approvals, ensuring quality to your work. In addition, it is possible to easily size the ideal anchorage system through the Hard DesignFix software.

The strongest injectable adhesive in the market

Its formulation with mix ratio 3:1, high percentage of high-grade raw material in its composition and absence of non-reactive diluent, providing high-performance to the chemical anchor bolt EP 131 making it the strongest slow curing adhesive in the market.

In addition, the anchor bolt slow cure provides stronger molecular binding between the concrete and adhesive.

Quality assurance

EP 131 has international approval that assures higher safety to your work.

The certification ETA – 13/0570 – Option 1, assures that the EP 131 passes tough the most comprehensive anchorage battery of tests, thus comprising the loads for application in fissured concrete, from 20 to 50 Mpa, combined traction and shearing loads, distance of edges and between anchorages, and application in regions of seismic tremor and high vibration rates.

Sizing with no difficulties

Using the injectable adhesive EP 131 , you will have exclusive access to the Hard DesignFix software to easily size the ideal anchorage system specifications to your project, according to the main international standards.