Screw is not all the same! So, choosing the best self-drilling screw for metal roofing is a more complicated task than it seems and requires a lot of attention. Once the right screw can extend the life of the entire metal roof and helps to prevent the entire structure from being compromised by leaks and corrosion.

We have listed below the main points to consider when choosing the self-drilling screw for metal roofing. Keep reading and clarify all your questions with this complete guide!

Sewing and fixing: what’s the difference?

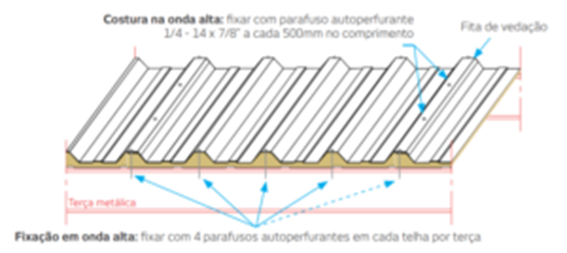

Did you know that there are two types of self-drilling screws for metal roofing? Fixing screws are used to fasten metal tiles to pullins. While the sewing ones are used to join one tile to the other, and we can find two most common types: drill point and needle point. On our blog, we have a complete article to explain the difference between the two types of fasteners for sewingclick here and check it out.

The main difference between the sewing and the fixing screws is their body diameter and the size of their tip. The seam fasteners have a larger body and a smaller tip – causing the plates to be pulled against each other -, while the fasteners are just the opposite.

Using the correct screw for each application is the first step to avoid problems. Once you install the fixing screw in place of a sewing screw, for example, it will weaken the application, as there will not be a correct union between the sheets. By doing this, the expansion or movement of the cover is enough for this screw to loosen, compromising the fixing points and the watertightness of the roof.

What are the main functions that a self-drilling screw for metal roofing should have?

We have listed below the four main functions that a self-drilling metal roofing screw should have. Check out!

1. Bore;

The first thing a self-drilling screw should do is drill. This function is basic, but not irrelevant. Paying attention to the tips available on the market – which is directly linked to the thickness to be fixed – and the application range can help bring more productivity to the work.

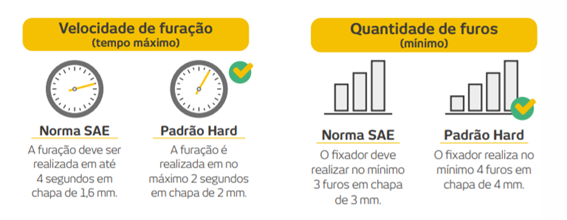

Hard fixing screws have a SuperBit drill bit, which guarantees high drilling performance. This ensures faster drilling, half the time recommended by SAE Standard J78 (Steel Self-Drilling Tapping Screws), which deals with steel self-drilling screws. In addition to that, the Hard fastener supports drilling at least four holes in 4mm sheet metal, while the SAE Standard recommendation is three holes in 3mm sheet metal.

In addition to the drill point sewing screw, Hard offers the Durs Stitch, which has a needle point. This feature guarantees no generation of filling during the hole, reducing the chances of corrosion in the cover.

2. Fix;

In screws, this action is done by the threads in the body of the fastener. The more threads, the greater the contact area of ??the thread with the plates, ensuring better tapping.

3. Seal;

When choosing the self-drilling screw for the metal cover, to ensure the seal, you need to pay attention to two points: the rubber washer and the head design. The first item is a barrier against liquids and gases, so it needs to be as resistant as possible. The quality of the washers can be verified through their level of purity, and the purer, the greater their durability. For example, EPDM Hard washers are 97% pure, meaning there is no chance of premature drying and breakage.

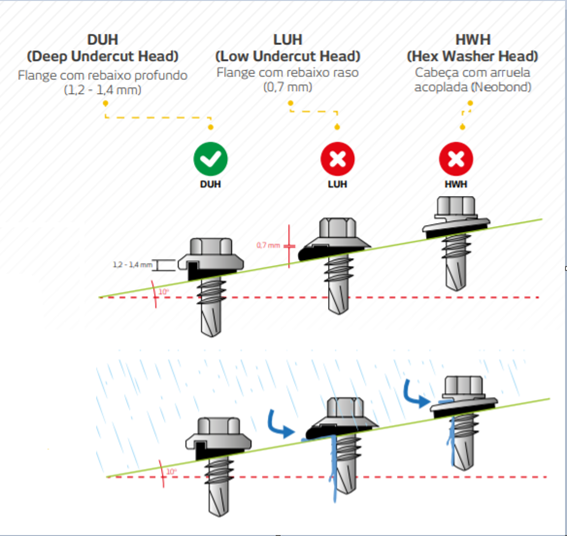

When it comes to the design of the heads, we can choose between three most common models. The HWH (Hex Washer Head) has a head with the neobond washer attached, the LUH (Low Undercut Head) has a flanged head with a shallow recess and the DUH (Deep Undercut Head) is a flanged head, only with a deep recess. See below the difference this makes to your coverage.

The DUH head, standard for Hard screws, perfectly accommodates the EPDM washer and absorbs up to 10º of inclination without risk of leaks. It means that it is more security for your coverage, drastically reducing the chances of leaks at these points. If you want to ensure an even tighter seal for your screws, keep reading because we have a very special bonus tip.

4. Resist the weather;

Any roof is exposed to the relentless aggressions of time and climate, so it is essential to have materials with the correct resistance for each environment. Did you know that the place where your metal roof is installed should influence the choice of coating for your bolt? According to the ISO 12944 Standard (Corrosion protection of steel structures by protective paint systems, part 2: Classification of environments), which classifies corrosive environments, there are five types of environments, they are maritime with high corrosion, industrial with high corrosion, maritime, urban industrial and urban rural. We explain these differences better in the video below, watch it!

In addition to weather resistance, the coating chosen must be compatible with the tile that will be used. Once there’s no reason to have a pre-painted tile or galvalume, for example, and using a white zinc plated fastener, since the screw’s strength will be much lower than the one in the sheet. In these cases, corrosion can start at the fastener and damage the entire structure.

Another common case is the fixing of aluminum tiles with white zinc plated screws, resulting in the known corrosion or galvanic pile. This pathology happens when two metals, with very different galvanic potentials, are in contact. Once the Durs line has aluminum in its Ecoseal® coating, these screws are ideal for aluminum tiles, once similar materials will not generate galvanic battery.

How many screws will I need for my cover?

Each project is unique, so a unique specification is required for each case. Hard recommends the use of at least four fixing screws per m² and two seam fixings per linear meter. Keep in mind that the unique characteristics of the Hard fasteners allow fixing in the low wave of the single tile, without any risk to watertightness. For thermo acoustic tiles or sandwiches, the installation indicated is in the high wave. For both cases, Hard has screws with the appropriate measurements.

We have a fastener sizing guide available in our catalog, check it out by clicking here. It’s on page 69!

Bonus tip! Provide extra protection for your fasteners

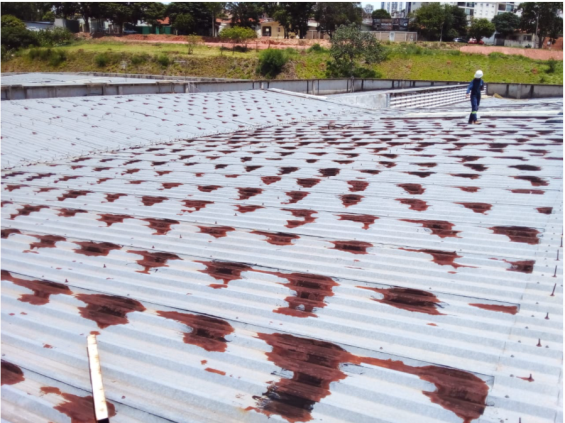

When it comes to metal roofing, Hard has over 35 years of experience. During all these years, we have already climbed on numerous roofs where pathologies have appeared even with the correct choice of screws. Now, you ask yourself: what was the problem then?

It’s that old story, as important as choosing the right product is to apply it correctly. In the case of screws, excessive or insufficient tightening can be the gateway to many problems. Therefore, it is very important to have a specialized workforce to carry out the installation.

As an extra protection, Hard developed the RR 500 ECO Sachet Sealant, a product that encapsulates the screw head and ensures 100% sealing. This solution is an extra guarantee for your coverage, once it protects even the screws that have been installed incorrectly. Check below how easy it can be to guarantee the watertightness of your metal roof.

Count on a specialist supplier of self-drilling screws for metal roofing

Choosing the right metal roofing screw is as important as having reliable suppliers. When you trust Hard Group’s fasteners, you can count on the solutions of a specialist for over 35 years in fastening and sealing metal roofs.

To meet all levels of aggression to which a cover is exposed, there are four lines of high performance screws available: Durs, with exclusive Ecoseal coating; Durs Color Head, with Ecoseal plus colored head; SS-302 Cap, with stainless steel cap on the head; and, Zaphir, item made of 304 stainless steel. They are the only self-drilling machines with FM Approved approval in Brazil.

In addition to that, to ensure Hard level quality, all screws undergo salt spray (Salt Spray) and acid rain (Kesternich) tests. Because of this stringent quality standard, Hard has delivered over one billion metal roofing fasteners to customers without any recorded corrosion defects.

Do you want a watertight, safe and durable metal roof? So, check out the Hard solutions for your work. Contact us now and one of our experts will help you find the best solutions.

Comentários

Ainda não há comentários. Seja o primeiro a comentar.