SMP 325 Pre-molded sealant

Hybrid Silicone Polyurethane Adhesive and Sealant for Expansion Joints

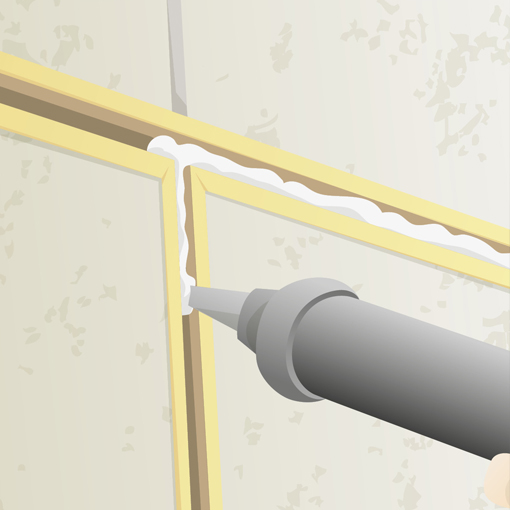

The pre-molded SMP 325 sealing adhesive is suitable for sealing expansion joints in pre-molded panels. Designed to provide better durability, it can also be applied over damp surfaces, without the risk of bubble formation.

Durability and resistance

The Anti UV-B additives, which can be found in the composition of the Pre-molded SMP 325, provide a sealant with high durability to weather and climatic agents.

The construction work doesn’t stop after it rains

The high percentage of base polymers in its composition allows the Pre-molded SMP 325 to be applied on damp concrete, preventing you from having to wait until the sun comes out to have your work dried.

Beautiful facade without infiltration

The solvent-free and isocyanate-free composition prevents bubbles to emerge during the curing process of the SMP 325 Precast. When the bubbles break with the expansion of the facade, they generate infiltration points in the structure, in addition to compromising the building aesthetics.

Previous: Hardthane® SMP 325. The package has changed, but you don’t have to worry: the product still has the same quality as ever. And most importantly: its formula remains the same.